Introduction:

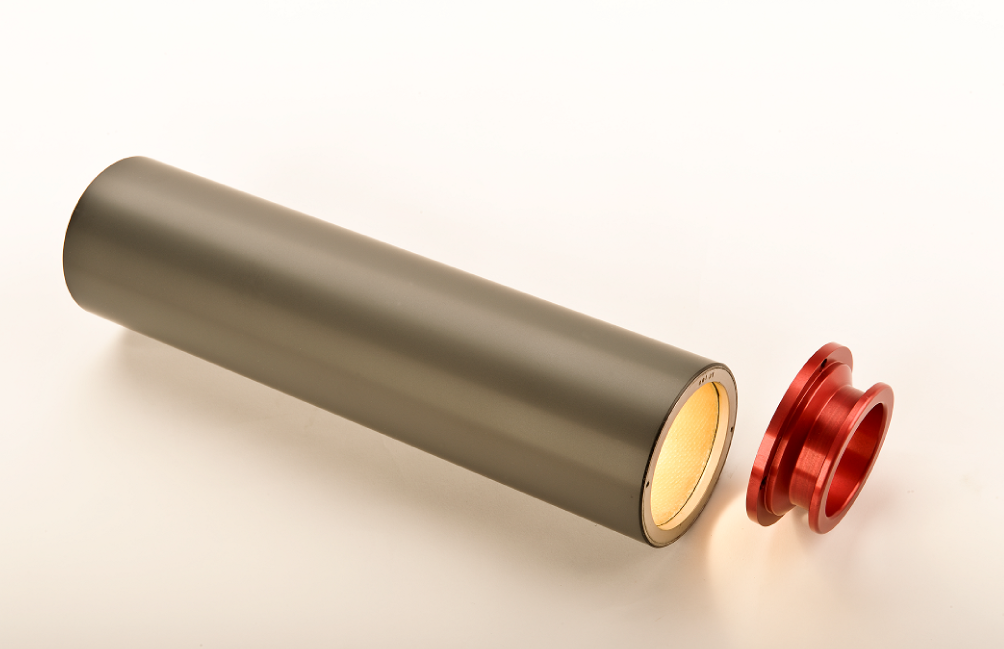

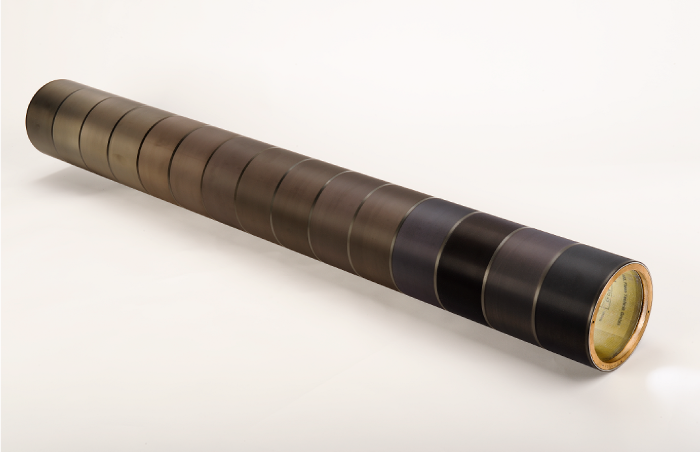

We are authorized agent, strategic partner for M/s Sandon Global Engraving Technology Limited, UK based company, is an award-winning manufacturer of Anilox rolls and sleeves used in the flexographic, gravure, lithographic and metal decoration print industries, worldwide. Uniquely manufacture our anilox rollers, mandrels, sleeves, and end-rings inhouse delivering total quality control. Our wide-web customers benefit from our technical support as part of the design process to ensure precision and consistency in volume transfer, line count, porosity, and hardness characteristics. Our dedicated staff and a global network of agents and distributors work tirelessly to improve our laser engravings, led by a solution-focused approach. Customers also benefit from our range of ancillary products, including sleeve protection covers, volume measuring equipment, bespoke ultrasonic cleaning systems, and sleeve storage.

Sector Experience

Other Markets

Tissue and non woven

Carton

Litho (Varnish Applications)

Metal Decorating

Lamination Adhesives (Gravure and Flexo Applied)

Tissue and non woven

Carton

Litho (Varnish Applications)

Metal Decorating

Lamination Adhesives (Gravure and Flexo Applied)

Anilox Coating Performance

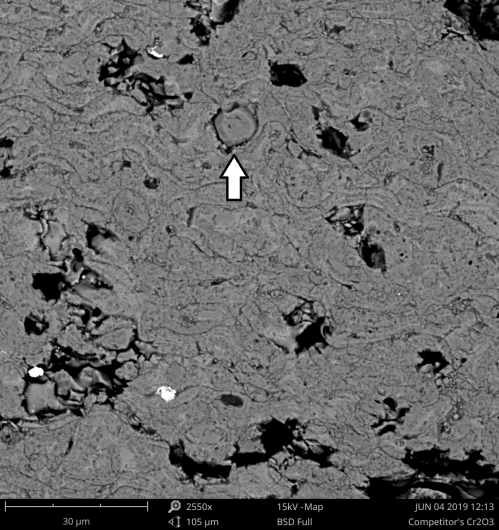

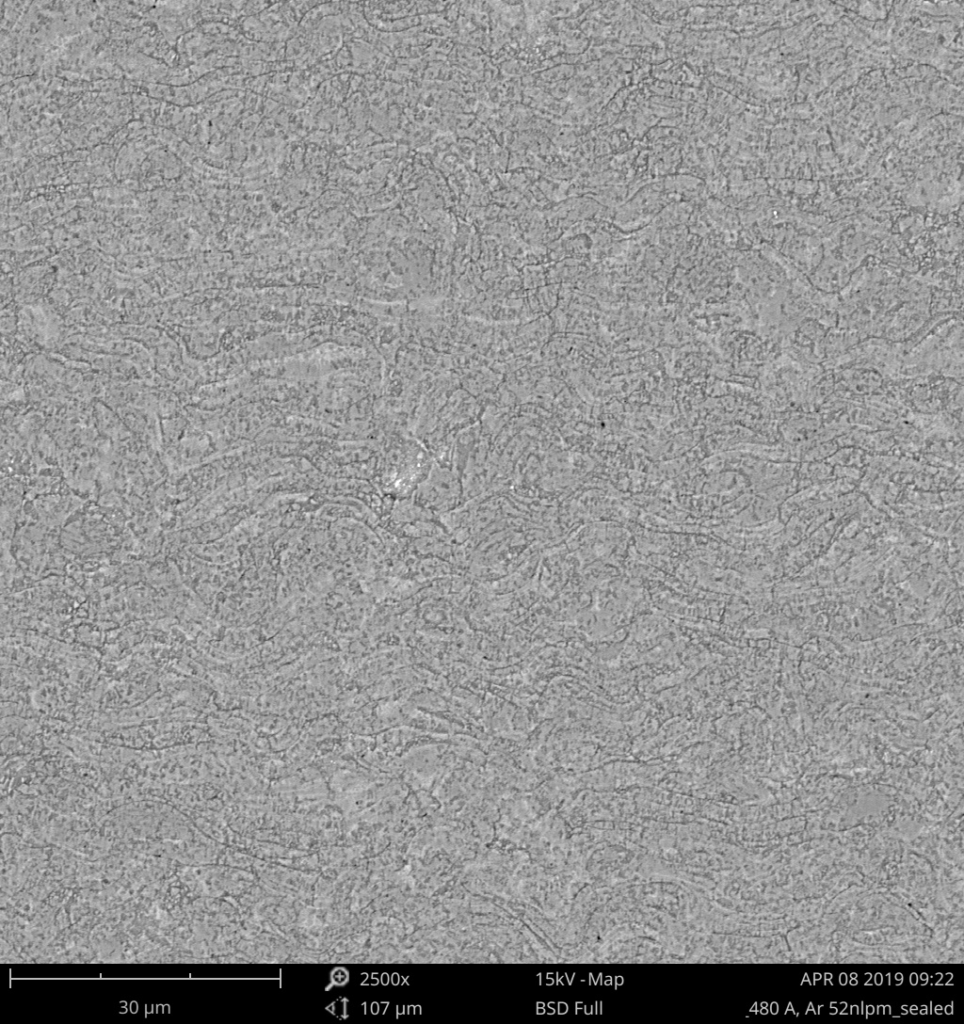

SEM X2500 Magnification

Competitor Surface Scan

Sandon Global Surface Scan

Surface corrosion is the result when coating controls are not in place.

Analysis of the surface shows very high porosity and very low hardness around 500 Vickers with large pieces of un-melted ceramic trapped within the coating structure

Surface corrosion is the result when coating controls are not in place.

Analysis of the surface shows very high porosity and very low hardness around 500 Vickers with large pieces of un-melted ceramic trapped within the coating structure

PRINT TECHNIQUE – Wideweb & Narrowweb

The award-winning anilox rolls and cylinders are designed to meet specific requirements and challenges set by the Wide-Web, Narrow Web Flexo,Gravure and Lithographic print markets.

Sandon Global manufacture and supply both new and refurbished laser engraved anilox. No single step of our production process is outsourced, guaranteeing total quality control. Our methodical approach assures the extended lifespan of our anilox, delivering print consistency and repeatability of colour for our customer base day in, day out.

Each of the engraving formats have been developed to achieve optimised results with solvent and waterbased inks in HD process, solid, vignette, white and various coating applications.

Whatever your print requirement Sandon Global will have the ideal anilox to meet your print needs.

Sandon Global, also supply a range of ancillary products to support the product and meet the cleaning and maintenance demands of an industrial print operation.

The award-winning anilox rolls and cylinders are designed to meet specific requirements and challenges set by the Wide-Web, Narrow Web Flexo,Gravure and Lithographic print markets.

Sandon Global manufacture and supply both new and refurbished laser engraved anilox. No single step of our production process is outsourced, guaranteeing total quality control. Our methodical approach assures the extended lifespan of our anilox, delivering print consistency and repeatability of colour for our customer base day in, day out.

Each of the engraving formats have been developed to achieve optimised results with solvent and waterbased inks in HD process, solid, vignette, white and various coating applications.

Whatever your print requirement Sandon Global will have the ideal anilox to meet your print needs.

Sandon Global, also supply a range of ancillary products to support the product and meet the cleaning and maintenance demands of an industrial print operation.

Engraving Innovators-WIDE – WEB

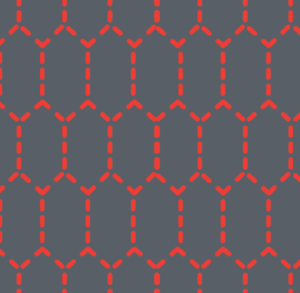

COMBINATION

(FLUID FP)

The semi-channelled Combination engraving (also known as Fluid FP) is designed for use in wide web flexographic print processes. The open nature of the engraving offers many advantages to printers summarised below.A semi-channelled engraving enabling controlled ink flow

Ideal for High Opacity White

Extended lifespan in comparison to conventional engravings

Combines solid and tone on a single plate

Good release characteristics

Increased scoring resistance due to smooth micro-polish finish

A semi-channelled engraving enabling controlled ink flow

Ideal for High Opacity White

Extended lifespan in comparison to conventional engravings

Combines solid and tone on a single plate

Good release characteristics

Increased scoring resistance due to smooth micro-polish finish

CONVENTIONAL 60º

(CLASSIC)

The 60° Conventional engraving (or Classic) is a multi-functional anilox and offers wide web printers consistent print results for both process and solid print on a broad range of substrates. The open cell structure delivers excellent release characteristics.

A 70% open cell structure aids ink flow

Multi-functional engraving

High cell wall ratio maximising ink release

Process and solid print

A 70% open cell structure aids ink flow

Multi-functional engraving

High cell wall ratio maximising ink release

Process and solid print

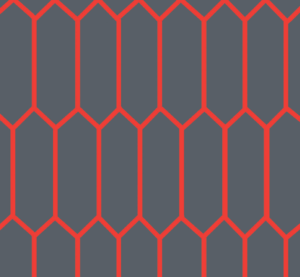

HIGH VOLUME PROCESS

(HVP)

The High Volume Process (also known as HVP) is an intermediate anilox that was designed to combine high line counts with high volumes for solid and tone print.

The elongated cell design allows us to increase the print latitude in comparison to conventional specifications. Key benefits include;

Versatile engraving used for solids, mechanical tints,vignettes, fine line text and clean reverse out print

Combines solids and tonal print on the same plate

Easy cleaning

Reducing anilox inventory and press downtime

Enhanced lay down, reducing pin-holing on solids

Improved wear characteristics, allowing cells to maintain good cell ratios characteristics

Versatile engraving used for solids, mechanical tints,vignettes, fine line text and clean reverse out print

Combines solids and tonal print on the same plate

Easy cleaning

Reducing anilox inventory and press downtime

Enhanced lay down, reducing pin-holing on solids

Improved wear characteristics, allowing cells to maintain good cell ratios characteristics

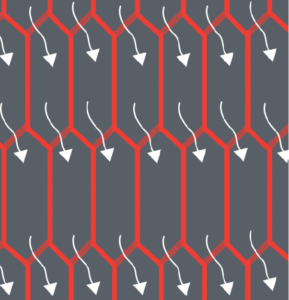

HIGH DEFINITION PROCESS 75º

(IPRO)

Our original High Definition 75º engraving (also known as IPRO) harnesses the characteristics required to achieve vivid colours through controlling opacity whilst reducing dot bridging / dot gain. Other benefits include;

75º engraving achieves a high line count reducing dot gain and bridging

Allow printers to make the most of advancements in reprographics

Vivid HD colours

Gaps in cell walls to reduce surface tension and promote ink release

Inter-linking cells deliver HD print quality

Consistent ink transfer, up to 800 mpm

Reduced ink starvation compared to a standard hexagonal cell format

75º engraving achieves a high line count reducing dot gain and bridging

Allow printers to make the most of advancements in reprographics

Vivid HD colours

Gaps in cell walls to reduce surface tension and promote ink release

Inter-linking cells deliver HD print quality

Consistent ink transfer, up to 800 mpm

Reduced ink starvation compared to a standard hexagonal cell format

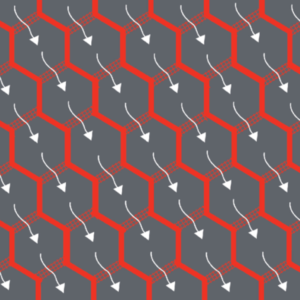

HIGH DEFINITION PROCESS 61º

(XPRO)

As High Definition print is becoming the norm in the

wide-web world we have developed an engraving solution for this purpose. A 61º engraving (also known as XPRO) is also ideal for vignette and solid pantone colours. Used typically with high resolution plates our robust cell peaks and channelled cell walls offer a range of benefits including;

Improved wear resistance at high resolution

Reduced risk of scoring, wear and engraving damage

Robust high peaks and channels to aid ink release

Reducing ink starvation, delivering vivid HD colours

Consistent ink transfer up to 800 mpm

Reduced plugging or cell blockage

61º engraving achieves a high line count reducing dot gain and bridging

Improved wear resistance at high resolution

Reduced risk of scoring, wear and engraving damage

Robust high peaks and channels to aid ink release

Reducing ink starvation, delivering vivid HD colours

Consistent ink transfer up to 800 mpm

Reduced plugging or cell blockage

61º engraving achieves a high line count reducing dot gain and bridging

Engraving Innovators NARROW – WEB

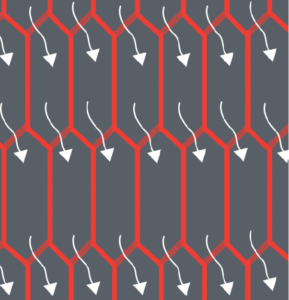

COMBINATION PRINT 75º

(FLUID UV)

The key benefits of our semi-channelled combination engraving

(also known as Fluid UV) solid, tone and HD process work and include;

Solid & Tone on one plate

HD process print and reduced dot gain

Minimise ink “spitting” and “pin-holing”

A semi-channelled engraving enabling controlled ink flow leading to“clean”print

Reduced doctor blade vibration due to smooth cell micro-finish

Vibrant colours

Reduce anilox inventories

Extend lifespan on wear compared to conventional 60ºengravings

Solid & Tone on one plate

HD process print and reduced dot gain

Minimise ink “spitting” and “pin-holing”

A semi-channelled engraving enabling controlled ink flow leading to“clean”print

Reduced doctor blade vibration due to smooth cell micro-finish

Vibrant colours

Reduce anilox inventories

Extend lifespan on wear compared to conventional 60ºengravings

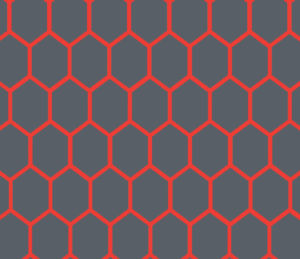

PROCESS & SOLID 60º

(FLUID HEX)

Our semi-channelled 60º engraving (also known as Fluid HEX) is far from conventional. In that it can be used for process and solid work on a broad range of substrates. It’s point of difference includes;

“Open” hexagonal cell design encourages ink flow

Process and tone

Strong solids

Minimise ink “spitting” and “pin-holing”

Improved release characteristics leading to “clean” print

Reduced doctor blade vibration due to smooth cell micro-finish

Like for like replication of standard 60º specifications

“Open” hexagonal cell design encourages ink flow

Process and tone

Strong solids

Minimise ink “spitting” and “pin-holing”

Improved release characteristics leading to “clean” print

Reduced doctor blade vibration due to smooth cell micro-finish

Like for like replication of standard 60º specifications

HIGH DEFINITION PROCESS 61º

(XPRO)

As High Definition print is becoming the norm in the narrow-web world we have developed an engraving solution for this purpose.

A 61º engraving (also known as Xpro) is ideal for both process and vignette print. Used typically with high resolution plates our robust cell peaks and channelled cell walls offer a range of benefits including;

61º engraving reduces the risk of moire (or screen clash)

Inter-linking cells deliver HD print quality

Reduced wear and reduced scoring

Precision volume control Reduced plugging

Consistent ink transfer at high speed

As High Definition print is becoming the norm in the narrow-web world we have developed an engraving solution for this purpose.

A 61º engraving (also known as Xpro) is ideal for both process and vignette print. Used typically with high resolution plates our robust cell peaks and channelled cell walls offer a range of benefits including;

61º engraving reduces the risk of moire (or screen clash)

Inter-linking cells deliver HD print quality

Reduced wear and reduced scoring

Precision volume control Reduced plugging

Consistent ink transfer at high speed

HIGH OPACITY WHITE

(HOW)

High Opacity White engraving (also known as HOW) was developed in partnership with a plate, ink and tape manufacturer, with the shared aim of delivering a rotary screen alternative opaque white for narrow-web application. Conventional thinking has been replaced with an anilox that gives you total control. We can offer 4 different volume levels to suit the text and solid density required.

A summary of the key benefits include;

Screen alternative opaque white without pin-holing

Available in 4 opacity levels

Maintain press speed Reduces ink reticulation

Eliminates costly screen heads

Improve print efficiency

Easier to clean

Screen alternative opaque white without pin-holing

Available in 4 opacity levels

Maintain press speed Reduces ink reticulation

Eliminates costly screen heads

Improve print efficiency

Easier to clean

HIGH OPACITY COLOUR

(HOC)

Our High Opacity Colour engraving (also known as HOC) removes the need for a backing white to achieve dense, opaque and strong colours. Developed in tandem with the High Opacity White engraving it enables printers to lay heavy coat weights to achieve the required opacity across the full colour gamut without reducing press speed. Summary benefits;

Holds fine point text without filling in

Screen quality opaque colour without pin-holing

Reduces ink reticulation

Maintain press speed

Eliminates costly screen heads

Improve print efficiency

Easier to clean than conventional engravings

No backing white required

Holds fine point text without filling in

Screen quality opaque colour without pin-holing

Reduces ink reticulation

Maintain press speed

Eliminates costly screen heads

Improve print efficiency

Easier to clean than conventional engravings

No backing white required

ANCILLARY PRODUCTS

ANI-CHECK INSPECTION

Ani-Check is a fast, simple and accurate tool for measuring anilox volumes. Based on the reading of an electrical magnetic field, Ani-Check allows print operators to quantify the condition of the anilox in their inventory.

OVERVIEW: Assessing the condition of your anilox cells is vital to achieving the best possible print results and minimises down time. Volume checking after cleaning is best practice and enables Print Managers to manage their anilox inventory.

Ink manufacturers also use the readings to formulate inks and coatings so clean anilox cells and accurate volume readings lead to accurate colour matching and production efficiency.

ADDED VALUE: Sandon Global provide full training and an annual equipment calibration.

KEY FEATURES: Minimum Press downtime / Fast Results

No calculations required / Digital Reading

ANI-SCOPE INSPECTION

Used in conjunction with the Ani-Check, the Ani-Scope is

designed as a simple way to check the condition of anilox engravings.

OVERVIEW: The microscope is available with a variety of magnifications. Enabling print managers to quickly ascertain levels of cleanliness, wear and potential damage on the anilox engraving. The Ani-Scope can be linked to a smart phone and capture images efficiently. Anilox refurbishments and cleaning schedules can be planned. Saving valuable press time and maintaining quality standards.

ADDED VALUE: Sandon Global provide full training and an annual equipment calibration.

KEY FEATURES:

MAGNETIC BASE FOR EASE OF USE

SMART PHONE COMPATIBLE

MAGNETIC BASE FOR EASE OF USE

SMART PHONE COMPATIBLE

NARROW WEB ULTRASONIC CLEANER

OVERVIEW:

We supply “Soft Clean” ultrasonic cleaners that provides fast, effective and safe cleaning for your entire inventory. Bespoke designs are available to meet your exact anilox dimensions and anilox inventory. The equipment has a number of features such as cleaning cycles and in-built diagnostics to ensure anilox are cleaned efficiently whilst retaining optimum performance.

KEY FEATURES:

IN-BUILT DIAGNOSTICS TO IDENTIFY PRODUCT ISSUES

TOUCH SCREEN OPERATION

CUSTOMISED CLEANING CYCLES

BESPOKE CLEANING CHEMICALS TO MATCH INK TYPE

CHEMICAL DOSING SYSTEM

ANNUAL SERVICE PROGRAMMES AVAILABLE

FILTRATION SYSTEM

HIGH-QUALITY STAINLESS-STEEL CONSTRUCTION

OPTIONAL PROFESSIONAL CUSTOMER BRANDING

IN-BUILT DIAGNOSTICS TO IDENTIFY PRODUCT ISSUES

TOUCH SCREEN OPERATION

CUSTOMISED CLEANING CYCLES

BESPOKE CLEANING CHEMICALS TO MATCH INK TYPE

CHEMICAL DOSING SYSTEM

ANNUAL SERVICE PROGRAMMES AVAILABLE

FILTRATION SYSTEM

HIGH-QUALITY STAINLESS-STEEL CONSTRUCTION

OPTIONAL PROFESSIONAL CUSTOMER BRANDING

ANILOX CLEANING SOLUTION

Cleaning Formula 1 & 2

The ultimate cleaning chemical, for an instant clean. This will remove all types of ink and should be used for stubborn ink residue which cannot be removed with other chemicals. This chemical provides an intensive clean and should be used periodically to remove the most persistent dried inks alongside mechanical cleaning systems or softer cleaning fluids.

Cleaning Formula 4

Strong, less aggressive cleaning fluids, for all ink types. A good daily cleaning solution or for intensive cleaning between mechanical cleans.

Xpel Cleaning

For solvent based and UV inks. This is a very effective and quick working chemical for the removal of printing residues. Xpel gives a high percentage clean to the anilox cells and decreases the time usually required for an effective mechanical clean.

ANILOX SLEEVE STORAGE

Our range of versatile anilox sleeve storage solutions can be floor mounted, mobile or bench top modular systems. Built to your specification our storage solutions enable you to store all your print sleeves vertically.

Scalable solutions will fit most print rooms offering protection and easy access to your entire inventory of sleeves.

Summary features include:

MECHANICALLY DRIVEN

ADJUSTABLE SHELF HEIGHTS

SIMPLE SELF-ASSEMBLY

CAPACITY TO HOLD UP TO 600KG PER MODULE

EVEN WEIGHT DISTRIBUTION OF SLEEVES

SAFE MANUAL HANDLING

CUSTOMER BRANDING AVAILABLE

We also offer a range of narrow-web options and carousels.

MECHANICALLY DRIVEN

ADJUSTABLE SHELF HEIGHTS

SIMPLE SELF-ASSEMBLY

CAPACITY TO HOLD UP TO 600KG PER MODULE

EVEN WEIGHT DISTRIBUTION OF SLEEVES

SAFE MANUAL HANDLING

CUSTOMER BRANDING AVAILABLE

OUR PRODUCT VIDEOS

Contact us!

Enquiry Form

Head Quarters

8-1-364/B/72,Deluxe Colony, Toli chowki Sheikpet road

P.O.Golconda Fort -Hyderabad – 500008, Telangana State, INDIA

Call Or E-Mail us on:

Call us on:

+91 720 785 0642

Call us on:

+966 50 133 4297

Email us at:

info@flexconsultantit.com

Email us at:

Sales@flexoconsultantit.com

Flexoconsultant IT

8-1-364/B/72,Deluxe Colony, Tolichowki Sheikpet road P.O.Golconda Fort, Hyderabad, 500008, Telangana, India