Introduction:

We are authorised agent,strategic partner for; M/s GS Trading SA Luxembourg based company dedicated to supplying equipment solutions for the pre-press and post-press sector of the printing industry.

All of our equipment is designed and manufactured “in house” to our own testing standards. GS Trading has already done more than 800 installations worldwide, with the help of its very efficient distribution network in over 90 countries; we are able to bring a local technical support to the end-user.

GS Trading only company worldwide being able to reply to all needs in terms of Plate making:

Solvent washable flexo plate making from A3 size up to 52/80”

Water washable flexo plate making from A3 size up to 42’’/40’’ automatic inline system.

Waterwashable Letterpress, A3 up to 42”/60” size

Supplying of any spare parts and consumable.

UVA, UVC Lamps to provide on Flexo plate making equipment

Solvent Washable FlexoPlate Equipments

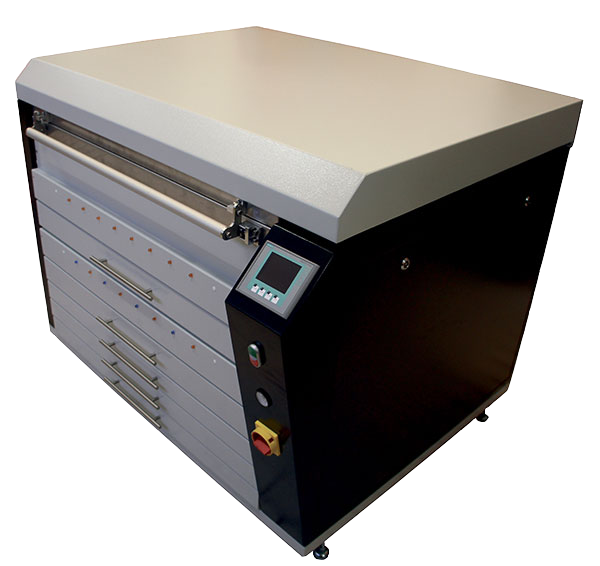

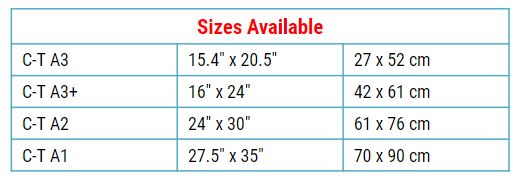

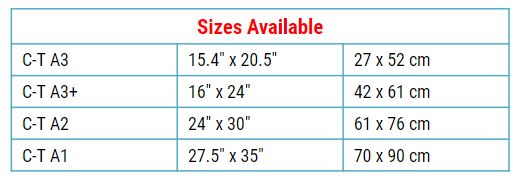

C-T All-in-one clamshell unit

Washout section: the plate is fixed face down on the plate holder. Relief washout is obtained by orbital movement of the plate over a brush frame.

Exposure: Pull out vacuum drawer with draw down sheet to hold plate during UVA exposure.

Light finisher & Px: Pull out drawer for UVC anti-tack exposure and UVA combined for post exposing the plate

Dryer: 2 Drawer for A3/A3+ and 3 Drawers for upper size with temperature control and exhaust blower.

Washout section: the plate is fixed face down on the plate holder. Relief washout is obtained by orbital movement of the plate over a brush frame.

Exposure: Pull out vacuum drawer with draw down sheet to hold plate during UVA exposure.

Light finisher & Px: Pull out drawer for UVC anti-tack exposure and UVA combined for post exposing the plate

Dryer: 2 Drawer for A3/A3+ and 3 Drawers for upper size with temperature control and exhaust blower.

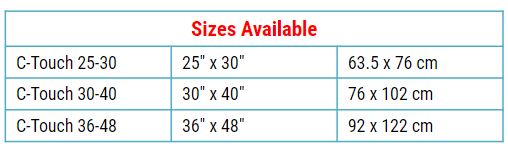

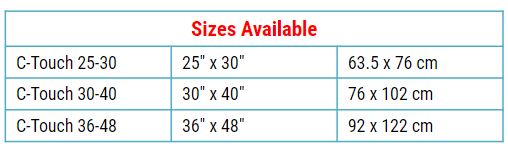

C-TOUCH All- in-one clamshell unit

Washout section: the plate is fixed face down on the plate holder

Relief washout is obtained by orbital movement of the plate over a brush frame. Automatic closing and opening of the brush frame at the end of the cycle.

Exposure: Pull out vacuum drawer with draw down sheet to hold plate during UVA exposure.

Light finisher & Px: Pull out drawer for UVC anti-tack exposure and UVA combined for post exposing the plate

Dryer: Three dryer drawers with temperature control and exhaust blower.

All configuration possible: WO / WO-D /…

Washout section: the plate is fixed face down on the plate holder

Relief washout is obtained by orbital movement of the plate over a brush frame. Automatic closing and opening of the brush frame at the end of the cycle.

Exposure: Pull out vacuum drawer with draw down sheet to hold plate during UVA exposure.

Light finisher & Px: Pull out drawer for UVC anti-tack exposure and UVA combined for post exposing the plate

Dryer: Three dryer drawers with temperature control and exhaust blower.

All configuration possible: WO / WO-D /…

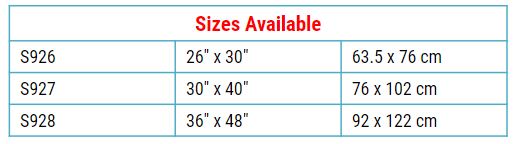

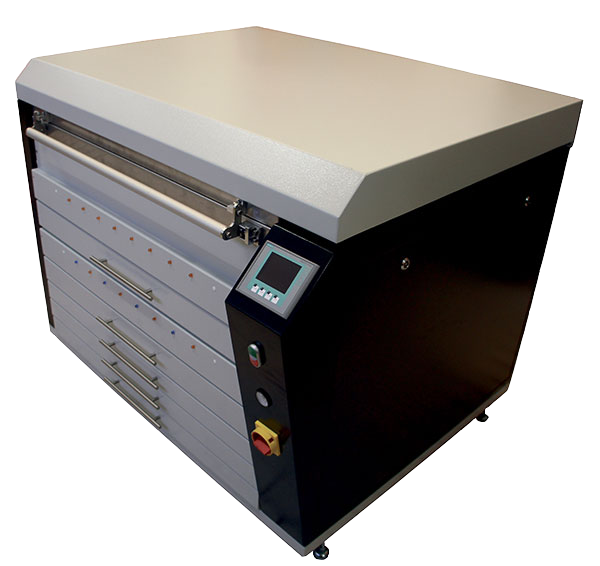

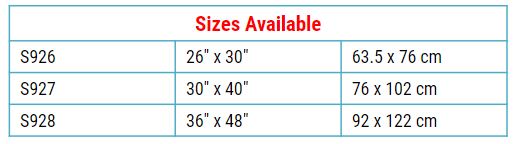

SYSTEM S900 All-in-one auto feed unit

Washout section : Formation of the plate relief is carried out by flat brushes, positioned automatically according to the plate parameters entered by the operator. Pre-wash section for black layer in option. Surface and back cleaning is by dedicated rotary brushes fed with fresh solvent to ensure a perfect result.

Plate transport is via a pin bar which can be easily adapted to different pitches according to the punch standard used. A plate punch suitable is available from us as separate unit.

Exposure : Pull out vacuum drawer with draw down sheet to hold plate during UVA exposure.

Light finisher & Px: Pull out drawer for UVC anti-tack exposure and UVA combined for post exposing the plate.

Dryer : Three dryer drawers with temperature control and exhaust blower.

Washout section : Formation of the plate relief is carried out by flat brushes, positioned automatically according to the plate parameters entered by the operator. Pre-wash section for black layer in option. Surface and back cleaning is by dedicated rotary brushes fed with fresh solvent to ensure a perfect result.

Plate transport is via a pin bar which can be easily adapted to different pitches according to the punch standard used. A plate punch suitable is available from us as separate unit.

Exposure : Pull out vacuum drawer with draw down sheet to hold plate during UVA exposure.

Light finisher & Px: Pull out drawer for UVC anti-tack exposure and UVA combined for post exposing the plate.

Dryer : Three dryer drawers with temperature control and exhaust blower.

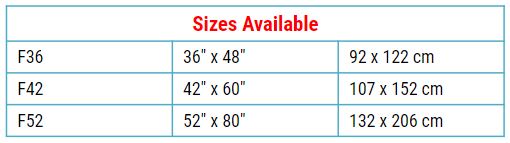

FORMULA All-in-one clam-shelve unit

The FORMULA comes complete with an exit table with warm air circulation. Formation of the plate relief is carried out by flat brushes,positioned automatically according to the plate parameters entered by the operator.

Pre-wash section for black layer integrated. Surface and back cleaning is by dedicated rotary brushes fed with fresh solvent to ensure a perfect result.

Heater Cooler of the solvent is part of the specification of that unit

Dual solvent tank for black layer removing section to avoid pollution of printing surface

The FORMULA comes complete with an exit table with warm air circulation. Formation of the plate relief is carried out by flat brushes,positioned automatically according to the plate parameters entered by the operator.

Pre-wash section for black layer integrated. Surface and back cleaning is by dedicated rotary brushes fed with fresh solvent to ensure a perfect result.

Heater Cooler of the solvent is part of the specification of that unit

Dual solvent tank for black layer removing section to avoid pollution of printing surface

Water Washable FlexoPlate Equipments

C-T All-in-one clamshell unit

Washout section: the plate is fixed face down on the plate holder. Relief washout is obtained by orbital movement of the plate over a brush frame.

Exposure: Pull out vacuum drawer with draw down sheet to hold plate during UVA exposure.

Light finisher & Px: Pull out drawer for UVC anti-tack exposure and UVA combined for post exposing the plate

Dryer: 2 Drawer for A3/A3+ and 3 Drawers for upper size with temperature control and exhaust blower.

Washout section: the plate is fixed face down on the plate holder. Relief washout is obtained by orbital movement of the plate over a brush frame.

Exposure: Pull out vacuum drawer with draw down sheet to hold plate during UVA exposure.

Light finisher & Px: Pull out drawer for UVC anti-tack exposure and UVA combined for post exposing the plate

Dryer: 2 Drawer for A3/A3+ and 3 Drawers for upper size with temperature control and exhaust blower.

C-TOUCH All- in-one clamshell unit

Washout section: the plate is fixed face down on the plate holder

Relief washout is obtained by orbital movement of the plate over a brush frame. Automatic closing and opening of the brush frame at the end of the cycle.

Exposure: Pull out vacuum drawer with draw down sheet to hold plate during UVA exposure.

Light finisher & Px: Pull out drawer for UVC anti-tack exposure and UVA combined for post exposing the plate

Dryer: Three dryer drawers with temperature control and exhaust blower.

All configuration possible: WO / WO-D /…

Washout section: the plate is fixed face down on the plate holder

Relief washout is obtained by orbital movement of the plate over a brush frame. Automatic closing and opening of the brush frame at the end of the cycle.

Exposure: Pull out vacuum drawer with draw down sheet to hold plate during UVA exposure.

Light finisher & Px: Pull out drawer for UVC anti-tack exposure and UVA combined for post exposing the plate

Dryer: Three dryer drawers with temperature control and exhaust blower.

All configuration possible: WO / WO-D /…

SYSTEM S900 All-in-one auto feed unit

Washout section : Formation of the plate relief is carried out by flat brushes, positioned automatically according to the plate parameters entered by the operator. Pre-wash section for black layer in option. Surface and back cleaning is by dedicated rotary brushes fed with fresh solvent to ensure a perfect result.

Plate transport is via a pin bar which can be easily adapted to different pitches according to the punch standard used. A plate punch suitable is available from us as separate unit.

Exposure : Pull out vacuum drawer with draw down sheet to hold plate during UVA exposure.

Light finisher & Px: Pull out drawer for UVC anti-tack exposure and UVA combined for post exposing the plate.

Dryer : Three dryer drawers with temperature control and exhaust blower.

Washout section : Formation of the plate relief is carried out by flat brushes, positioned automatically according to the plate parameters entered by the operator. Pre-wash section for black layer in option. Surface and back cleaning is by dedicated rotary brushes fed with fresh solvent to ensure a perfect result.

Plate transport is via a pin bar which can be easily adapted to different pitches according to the punch standard used. A plate punch suitable is available from us as separate unit.

Exposure : Pull out vacuum drawer with draw down sheet to hold plate during UVA exposure.

Light finisher & Px: Pull out drawer for UVC anti-tack exposure and UVA combined for post exposing the plate.

Dryer : Three dryer drawers with temperature control and exhaust blower.

Flexo Plate Cleaning

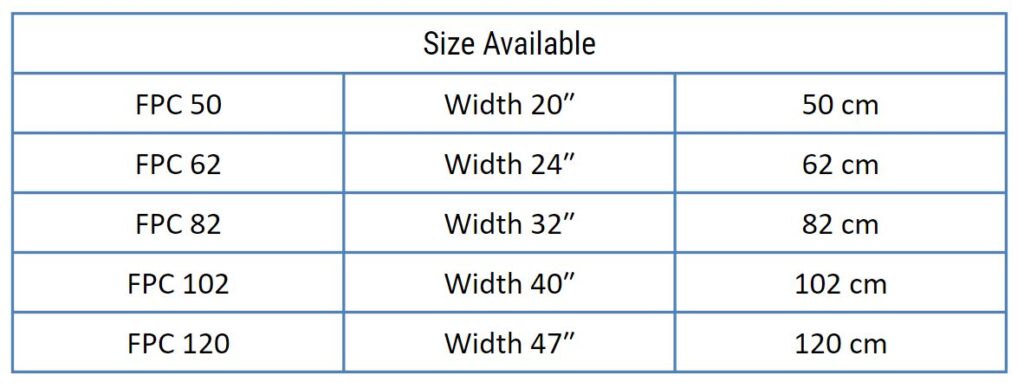

FPC I 4B – Automatic Plate cleaning

Automatic start and stop of cycle, plate can be feed one after the other one

New generation with high performance cleaning device

Different configuration available – 4 brushes (2 rotary + 2 round or 4 rotary or 4 fat brushes)

Option for:

Integrated Conveyor

Exit with gravity rolls or basquet

Automatic start and stop of cycle, plate can be feed one after the other one

New generation with high performance cleaning device

Different configuration available – 4 brushes (2 rotary + 2 round or 4 rotary or 4 fat brushes)

Option for:

Integrated Conveyor

Exit with gravity rolls or basquet

Consumables & Spares Supplies

Spares & Consumables

Brushes

Lamps

Vacuum Foil

UVA & UVC Lamps

Intensity measuring device

Brushes

Lamps

Vacuum Foil

UVA & UVC Lamps

Intensity measuring device

Contact us!

Enquiry Form

Head Quarters

8-1-364/B/72,Deluxe Colony, Toli chowki Sheikpet road

P.O.Golconda Fort -Hyderabad – 500008, Telangana State, INDIA

Call Or E-Mail us on:

Call us on:

+91 720 785 0642

Call us on:

+966 50 133 4297

Email us at:

info@flexconsultantit.com

Email us at:

Sales@flexoconsultantit.com

Flexoconsultant IT

8-1-364/B/72,Deluxe Colony, Tolichowki Sheikpet road P.O.Golconda Fort, Hyderabad, 500008, Telangana, India