Introduction:

We are authorised agent strategic partner for; M/s Lemorau is a growing and innovative company that produces Digital Printing, and finishing machines for the world-wide label industry.

“… Well established in the Portuguese market, have been growing internationally over the last years. Lemorau is now present in over 60 territories in the 5 continents….”

All the machines are developed, manufactured and assembled in house. Since 1987, all machines are designed, quality assured and practical, durable and most of all reliable that are manufactured according to the highest standards and go through rigorous quality control testing during multiple stages of production and upon completion

Our Products

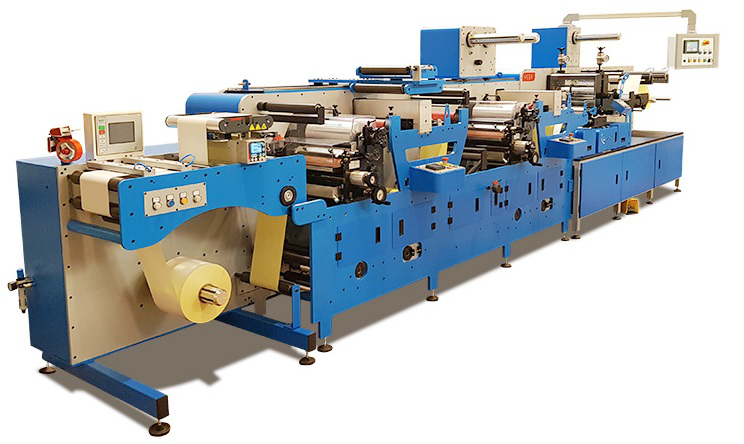

CUSTOMIZED MEBR+

According to Specific Requirements

- Un-winder module with splice table, web guide and servo nip in.

- 2 rotary/semi-rotary UV/Water based ink flexo unit in register

- Delam-relam

- Movable cold foil station over both flexo station

- Turn Bar

- Semi-rotary/ full rotaty die cutting station with speed pack, anvil roll with adjustable gap and pressure gauges

- Machine pre-register function for two flexo stations and die cutting unit

- Double Rewinder

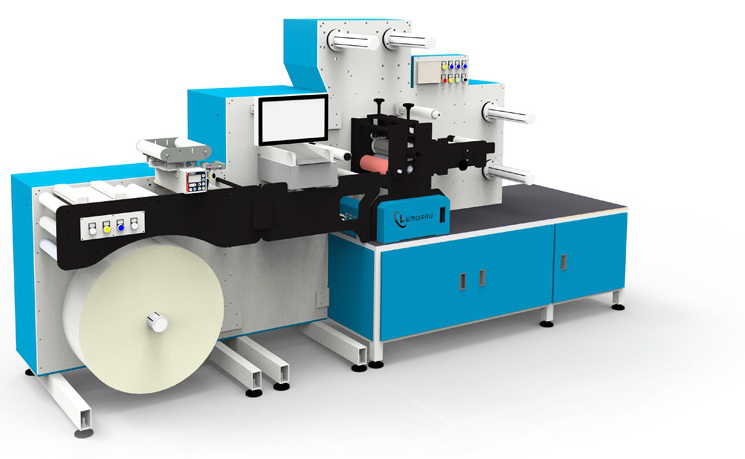

DIGI EBR+

Digital Printing, Coating and Finishing Machine

Digi EBR+ is a digital printing machine that can coat and die cut all in one process.

Based on SIRIUS MEMJET Technology, the Digi EBR+ can print with resolution 1600×1600 dpi full color, with web width ranging from 50 to 250 mm.

Due to the printing head cleaning function, the high printing quality is maintained during long runs. The Digi EBR+ runs in rotary and semi-rotary mode and can finish digital printed webs provided from others digital printing machines as well.

High production of white labels at max. speed 200 m/min.

Maximum Rotaty Maximum rotary speed 200 m/min (656 ft/min.) - Blank labels

Maximum rotary speed 120 m/min (394 ft/min.) - Die cutting to register

Maximum semi-rotary speed 40 m/min (131 ft/min.) dependent on plate size – Die cutting to register

Web width 250, 330, 400 mm (10, 13, 16 in)

Print resolution 1600×800 or 1600×1600 dpi

Print speed 18 m/min or 9 m/min (59 ft/min or 30 ft/min)

Print width 222,8 mm (8,77 in) length 2400 mm (94.5 in)

Ink system – NIAGARA INK

Four 2-liter ink tanks (CMYK)

Electronic web guide system with ultrasonic sensor which enables guiding of opaque and clear materials

Automatic web tension control system by servo motors – Constant and Taper

tension

STANDARD FEATURES:

- Maximum Rotaty Maximum rotary speed 200 m/min (656 ft/min.) - Blank labels

- Maximum rotary speed 120 m/min (394 ft/min.) - Die cutting to register

- Maximum semi-rotary speed 40 m/min (131 ft/min.) dependent on plate size – Die cutting to register

- Web width 250, 330, 400 mm (10, 13, 16 in)

- Print resolution 1600×800 or 1600×1600 dpi

- Print speed 18 m/min or 9 m/min (59 ft/min or 30 ft/min)

- Print width 222,8 mm (8,77 in) length 2400 mm (94.5 in)

- Ink system – NIAGARA INK

- Four 2-liter ink tanks (CMYK)

- Electronic web guide system with ultrasonic sensor which enables guiding of opaque and clear materials

- Automatic web tension control system by servo motors – Constant and Taper tension

MEBR+

Modular Digital Finishing Machine

MEBR+ is a digital finishing machine developed in a modular concept for its flexibility of configurations and the possibility of modules to be added or upgraded later on according to customer needs.

MEBR+ die cutting unit runs in full rotary and semi-rotary mode. Semi-rotary for short runs and full rotary for high speed longer runs. The registration tolerance is maintained during acceleration, deceleration and production time due to the latest servo technology.

MEBR+ is equipped with servo-driven compensator system which provides superior web tension control when the machine is running in semi-rotary mode.

STANDARD FEATURES:

- Maximum rotary speed 200 m/min (656 ft/min.) – Blank label

- Maximum rotary speed 120 m/min (394 ft/min.) – Die cutting to register

- Maximum semi-rotary speed 40 m/min (131 ft/min.) dependent on plate size Die cutting to register

- Web width 250, 330, 400 mm, other sizes (10, 13, 16 in, other sizes)

OPTIONAL EQUIPMENT:-

- Booklet label modul- Cold foil

- Corona treatment

- Delam/Relam

- Digital printing module Inkjet water based CMYK

- Digital printing module UV Inkjet 4-6 colors, White, Varnish

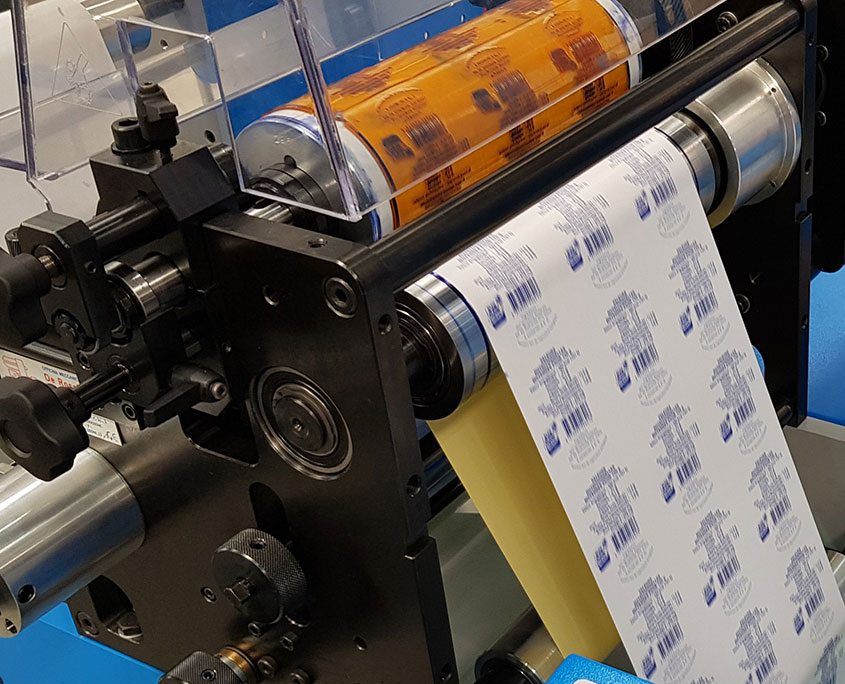

EBR

Die Cutting to Register Machine

EBR is a Full Servo Die Cut To Register Slitter Rewinder Machine. It allows digital and inkjet printed webs to be finished quickly and economically.

Using the latest servo drive technology the material can be converted into finished rolls or sheets at speeds up to 120 m./min. (398 ft/min.).

The machine can also die cut blank labels up to 200 m./min. (656 ft/min.), slitting and finishing all in one process. The registration tolerance is maintained during acceleration, deceleration and production time due the latest servo technology. Just three meters, is the average set up waste.

The internet connection allows remote assistance any time. The Servo Drive web tension control of the unwinder, matrix rewinder and rewinders allows a very accurate rewinding tension.

EBR is able to produce roll to roll as well as roll to sheet labels.

STANDARD FEATURES:

- Maximum speed for Blank Labels 200 m/min (656 ft/min.)

- Maximum speed Die Cutting to Register 120 m/min (394 ft/min.)

- Web width 250, 330, 400 mm (10, 13, 16 in)

- Electronic Counter (Labels/ Meters/ Rolls counter/ Total meters and labels Counter)

- Adjustable splice table with pneumatic clamps

- Electronic web guide system with ultrasonic sensor which enables guiding of opaque and clear materials

- Automatic web tension control system by servo motors – Constant and Taper tension 250 Job memory for easy and quick job set ups

EB

Die Cutting Machine

EB die cutting machine is an extremely efficient and precise machine built for high volume production of blank labels.

Each rewinder, unwind and waste matrix removal rewinder tensions are fully independent and adjustable on the touch screen panel.

Once the tension is selected and set, there is no need for the operator to readjust the tensions.

EB is able to produce roll to roll labels as well as roll to sheet labels. It is a very sturdy machine combined with the latest high technology.

EB has a very high work speed and produces excellent quality of finished rolls.

STANDARD FEATURES:

- Maximum speed 200 m/min (656 ft/min.)

- Web width 250, 330, 400, 550 mm (10, 13, 16, 22 in)

- Electronic Counter (Labels/ Meters/ Rolls counter/ Total meters and labels Counter)

- Adjustable splice table with pneumatic clamps

- Electronic web guide system with ultrasonic sensor which enables guiding of opaque and clear materials

- Automatic web tension control system by servo motors – Constant and Taper tension

- 250 Job memory for easy and quick job set ups

- 6 sets of circular knives with lateral adjustment

- 2 interchangeable pneumatic rewinders of 25, 40 and 76 mm diameter (1, 1.5, 3 in)

ICR 3

Inspection Slitter Rewinder Machine

ICR 3 inspection and slitter rewinder machine offers high working speed and excellent quality of finished rolls.

The inspection can be made with stroboscope, missing label detection system or with a 100% or 200% video inspection system.

With a user-friendly software and quick job changes due job memory functionality, makes ICR3 very practical and easy to use.

With the web guide allied with our tension control system and the standard features of the machine, makes ICR3 a high performance machine.

Each rewinder and unwinder tensions are fully independent and adjustable on the touch screen panel controlled by servo motors.

STANDARD FEATURES:

- Maximum speed for Blank Labels 200 m/min (656 ft/min.)

- Maximum speed Die Cutting to Register 120 m/min (394 ft/min.)

- Web width 250, 330, 400 mm (10, 13, 16 in)

- Electronic Counter (Labels/ Meters/ Rolls counter/ Total meters and labels Counter)

- Adjustable splice table with pneumatic clamps

- Electronic web guide system with ultrasonic sensor which enables guiding of opaque and clear materials

- Automatic web tension control system by servo motors – Constant and Taper tension 250 Job memory for easy and quick job set ups

CR 1000

Slitter Rewinder Machine

CR 1000 is a compact machine, very affordable and simple to use. It has been designed for slitting and rewinding substrates from a master roll 1000mm (3.2 ft) wide.

It is a very sturdy machine and available in a variety of configurations. Its designed and built-in- house, we can customize the machine according to customer needs.

CR 1000 is controlled through a color touch screen panel, which is very straightforward and user-friendly.

Each rewinder and unwinder’s tensions are fully independent and adjustable on the touch screen panel.

CR 1000 is able to run a wide range of substrates such as paper, cardboard and films.

STANDARD FEATURES:

- Maximum speed 100 meters per minute (328 ft/min.)

- Web width 1000 mm (39.3 in) or 1500mm (59 in)

- Electronic counter (Meters/Total meters/Rolls counter)

- Pneumatic unwind mandrel with lateral adjustment

- Pneumatic unwinder mandrel of 76 mm (3 in)

- Maximum unwinder diameter 800 mm (31,5 in)

- Maximum rewinder diameter 600 mm (24 in)

- Automatic web tension control system – Constant and Taper tension

- 250 Job memory for easy and quick job set up

- Automatic stop at master roll end with programmable end of roll function

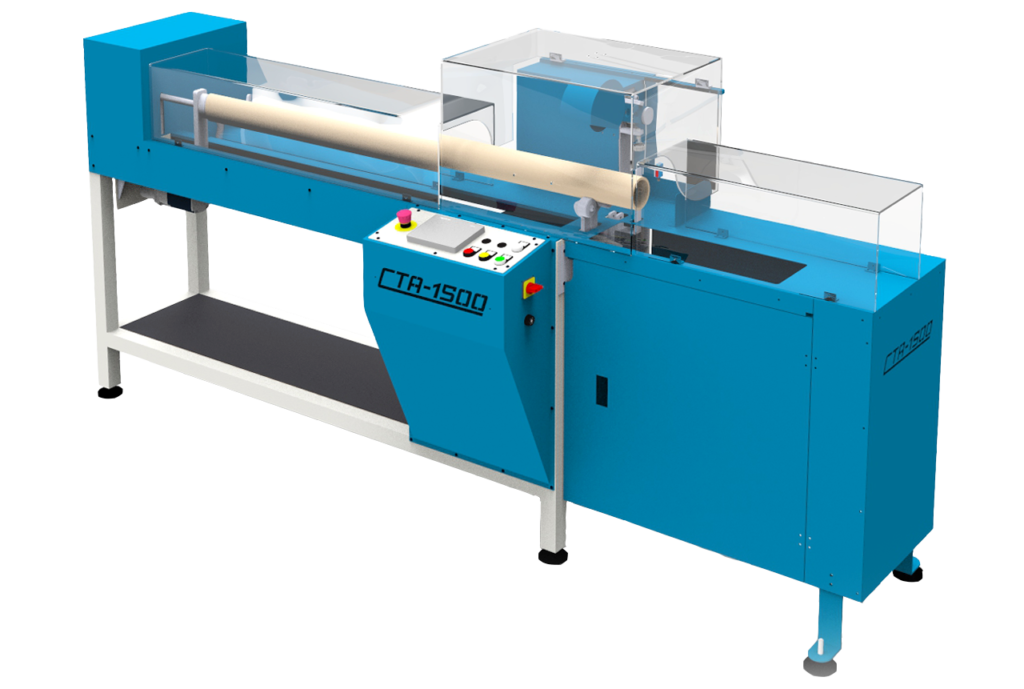

CTA 1500

Automatic Core Cutter

CTA 1500 is an automatic core cutter machine. Its function is cutting cores in a desired measure over its total length and in a selected quantity.

Built with heavy-duty components to exact specifications, it produces perfectly cut cores fast and accurately for years to come.

CTA 1500 is user-friendly and it includes a fully automated cutting cycle.

STANDARD FEATURES:

- Simple or multiple cut length from a single parent core (up to 4 different lengths)

- Automatic core length measurement

- User-friendly software

- Multi language touch screen

- Core positioning by servo motor

- Core edge trim function

- Core diameters 25, 40, 50, 76 mm (1”, 1.5”, 2”, 3”)

- Can cut up to 40 cuts/minute

- CE conformity certificated, user manual and electrical scheme

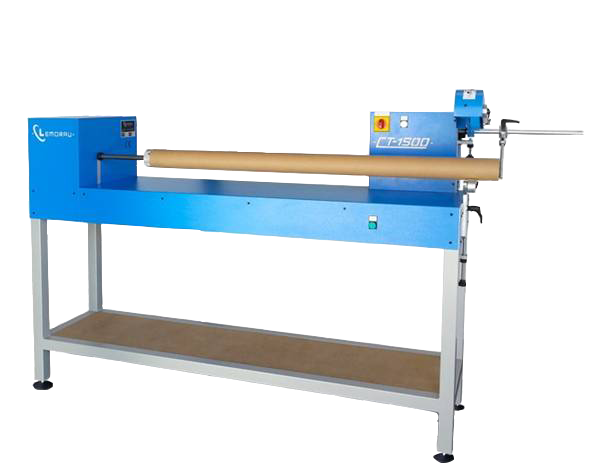

CT 1500

Manual Core Cutter

CT 1500 is a manual core cutter that is compact, efficient and cost effective.

It produces an accurate, clean, quality cut with quick and easy change-over for multiple core diameters and wall thickness.

CT 1500 is very easy to operate, after sliding the parent core onto the mandrel, the operator sets the end-stop, which determines the width of the cores cuts.

The operator then presses the start button, lowers the knife using the handle and cuts the core.

STANDARD FEATURES:

- Maximum core length up to 1500 mm (59”)

- Standard core diameter 25, 40, 50, 76 mm (1”, 1.5”, 2”, 3”)

- Other sizes up to 152 mm (up to 6”) as an optional

- Maximum measured cut length 330 mm (13”)

- Maximum wall thickness 6 mm (0.23”) cardboard

- Dual-hand control for operator safety

- CE conformity certificated, user manual and electrical scheme.

ER 400

Roll Lifter

ER 400 roll lifter is a portable equipment, capable of lifting rolls up 150 or 250 Kg (331 or 551 lbs). ER 400 has been introduced to improve manual handling operations and increase productivity, considering the scenario where operators find it necessary to call another colleague to change a roll. Is equipped with a safety brake for loading, unloading and transporting rolls safely. A mechanical device always ready anytime you need.

Contact us!

Enquiry Form

Head Quarters

8-1-364/B/72,Deluxe Colony, Toli chowki Sheikpet road

P.O.Golconda Fort -Hyderabad – 500008, Telangana State, INDIA

Call Or E-Mail us on:

Call us on:

+91 720 785 0642

Call us on:

+966 50 133 4297

Email us at:

info@flexconsultantit.com

Email us at:

Sales@flexoconsultantit.com

Flexoconsultant IT

8-1-364/B/72,Deluxe Colony, Tolichowki Sheikpet road P.O.Golconda Fort, Hyderabad, 500008, Telangana, India