Heart of the flexographic printing: Importance of anilox rolls in flexography

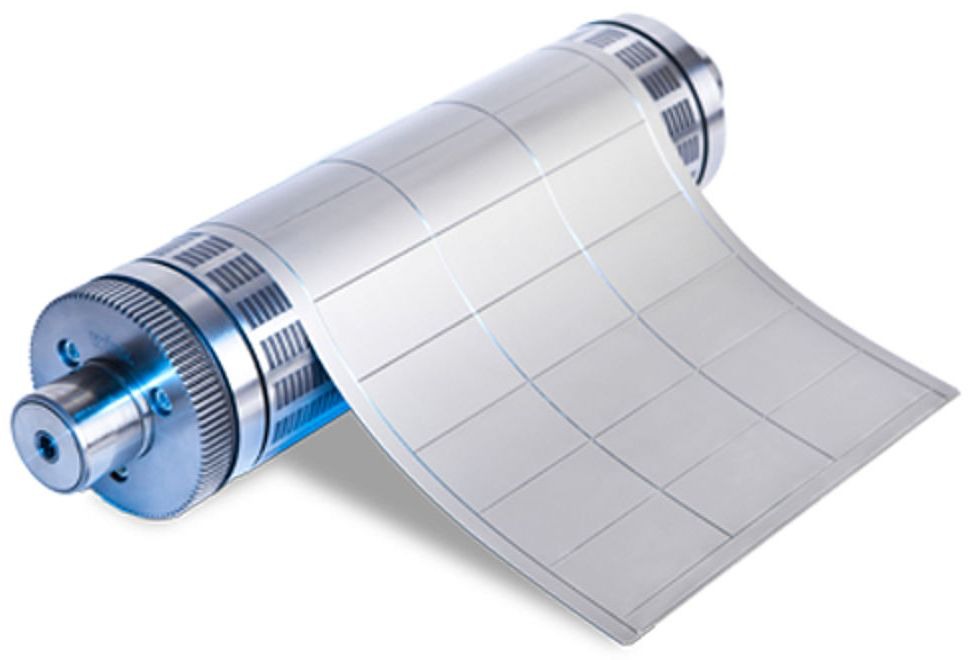

The anilox roll is what sets the flexographic industry apart from other printing discipline. In gravure the image cylinder makes contact directly with the ink. In offset and letterpress ink is transferred via smooth rollers to the printing plates. Flexography differs from these processes in that the inks is transferred to the anilox roll, whose […]

Heart of the flexographic printing: Importance of anilox rolls in flexography Read More »