In Mould Labelling Technology “IML”

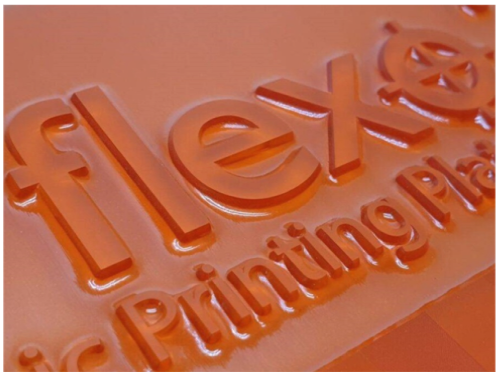

In Mould Labelling Technology “IML” THE IML PROCESS In-mold labeling, or IML, is an innovative technology that opens new horizons in the labeling process used for all types of injection-molded, blow-molded, and thermoformed plastic containers or parts. The IML process allows you to fuse in-mold labels (high-quality graphic images) to plastic in a single step […]

In Mould Labelling Technology “IML” Read More »