Pressure-sensitive... Why is it called that?

INTRODUCTION

It’s called “ pressure-sensitive” (PS) because all it takes is pressure to effect instant, all over bonding. Unlike other types of labeling, PS requires no glue, no water, and no heat. To apply a pressure sensitive label, just pull away the Backing (the liner) from the PS material (the facestock) .. and press it directly onto the item you are labelling. The result is instant adhesion with only slight pressure. Before the introduction of pressure sensitive, all that was available to the printer and the end-user was sticky paper.. Commonly known as Gum (gummed) paper, Gum paper both dry and wet, is no longer as popular for many applications

For several reasons:

- The water on the printing press must be controlled to an optimal level for good printability and press performance. If not controlled correctly, the excessive water activates the adhesive on the dry-gummed material…. resulting in the paper and its adhesive literally gumming up the press and causing downtime.

- The adhesive on pressure sensitive covers the entire surface efficiently, so adhesion is 100% corner-to-corner. No water is everneeded. The adhesive on dry-gummed must be activated by the application of water. Often the water does not cover the entire adhesive surface, allowing dry areas that do not adhere to the itme being labelled.

- Storage is often a problem for dry-gummed material. If too much moisture is present, the sheets may stick to themselves and cannot be used for printing.

For these reasons, many commercial, in-plant and instant print shops show a strong preference for pressure sensitive Products, Dry Gum products are still used and available in variety of face stocks.

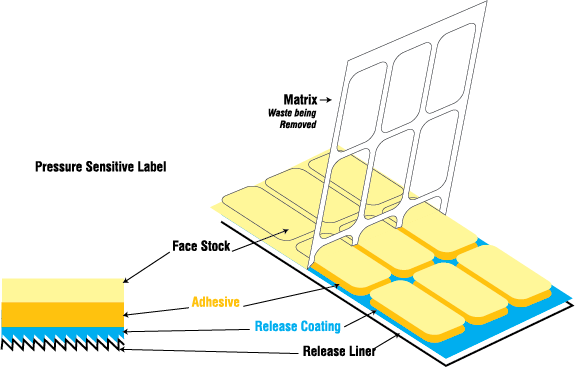

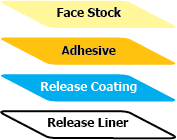

BASIC COMPONENTS OF A PRESSURE SENSITIVE LABEL

The Pressure Sensitive ‘Sandwich’

With pressure sensitive labels, unlike other label formats, there is more to the label than just a single material. The labels are actually composed of several different material components.

Construction

Face Stock – is the surface material. It can be paper, foil, film or cloth-material that’s designed to be printed and converted into pressure sensitive stock.

Adhesive – is designed as a coating layer to adhere to a wide variety of surfaces. An adhesive can be permanent or removable for long or short-term use.

Release Coating – is a special coating applied to a liner that regulates the correct adhesion release. The release level is a measure of the peel strength from a release liner.

Release Liner – protects the adhesive from contamination and is removed for simple application of the label.

Brief Explaination:

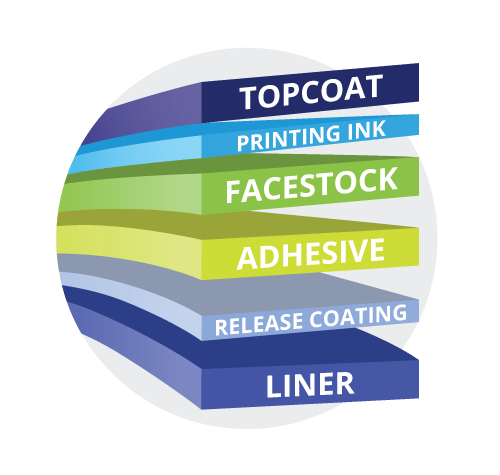

Topcoat

Topcoat can mean multiple thins in labelling; we are referring to the final protective layer after the print. This layer is designed to provide physical properties to ensure acceptable performance on the filling line, during distribution and consumer use, and can be used to enhance the shelf presence of the final product. There are two main types of topcoats available

Varnish

Coating applied (like an ink) to the surface; can be gloss, matte or both (multiple varnishes)

Laminate

a protective film that is applied to the top of the label and can provide a gloss or matte finish.

Facestock

The facestock is the outer material or the top ‘face’ of the label and is the material that ultimately is applied to the container. When the label is printed, the ink is printed on the facestock material . There are many different paper and film-based materials available based on your appearance and performance criteria. For example, a speciality paper might be chosen for a product to reflect the quality of the product, whereas a film might be chosen for a product that needs to withstand moist conditions during its life.

Adhesive

The facestock is backed by an adhesive layer that allows the label to stick to the container at application. There are several factors taken into consideration when selecting an adhesive

Container

The adhesive performance is related to the type of container surface (plastics, glass,metal). In the case of a plastic container, if it needs to be squeezable, the adhesive will need to accommodate squeezability.

Removability

Will the label need to be repositioned during application or by the consumer or does it need to be permanent. Application

Temperature

Will the labels to be applied to warm or cold fill containers? The adhesive must be able to adhere to the container at the required speed on the filling line as well as through the products life.

Environment

What are the environmental conditions at the time of application as well as during distribution and consumer use? Does the label need to withstand a wet or dry environment ? Is your product shelf stable or is it refrigerated or frozen ? The adhesive must be able to allow the label to function at expected levels through its life.

Release Coating

The release coating is applied to the top of the liner providing the appropriate release level of the label from the liner during application to your container or package.

Liner

The liner is an important component of the pressure sensitive label sandwich. The liner backs the facestock material allowing for the label to be transported through the label applicator and onto the container. The liner also acts as the die-cutting base in the label manufacturing process. Liners are available in papers and films, of various thicknesses and weight. The line speed during application (as wellas the final label design) will dictate what liner options will be advised for use on a project.

About the Author:

Mohammed Abdul Haleem

Email: packagingprinting@consultant.com

With almost 27 years of experience in the printing industry, he offers proactive recommendations on anilox roll specifications, flexographic printing sleeves, testing, inventory management, flexographic equipment applications, training, representation from experience in technical sales, marketing, production, technical service, parts, and supplies. His experience covers the spectrum of flexographic markets including wide web flexible packaging, narrow web, tag & labels, foil, folding carton, corrugated packaging applications.