Introduction:

We represent the well-known manufacturer M/s Tamburini s.r.l, Italy – to supply Flexographic Printing Plate Mounting Sleeves – Rubber Roller for ink metering, etc.

Technological up-dating is a philosophy of Grafiche Tamburini that involves staff and each department: the graphic department is equipped with permanently updated computers and software in order to meet every request; the internet is a channel of primary importance that offers a detailed website showing a wide range of services as to materials management in order to easily and quickly receive and deal with orders.

The last technological goals as far as concerns flexographic printing are GTSleeve HQ Speed, GTSleeve Speedy, and GTSleeve Combi.

Using a mandrel air system for mounting and unmounting sleeves, the adapters have a steel ring with an incorporated notch. The adapters have a further air inlet to ease sleeve mounting and they can be combined with various types of sleeves. Available in polyurethane or with a conductive external layer.

The sleeve thickness needed is significantly reduced. This is a cost-saving benefit for your production runs. The number of air inlets along with the bridge surface range from 1 to 3 holes of Ø 2mm. All adapters are durable, scratch and solvent resistant when handled correctly.

Why Flexo plate mounting Sleeves?

Whenever a flexo print job is likely to be rerun at a later date, it pays to use Flexo plate mounting sleeves. Instead of mounting plates directly to cylinders, mount them on inexpensive GTSleeve HQ Speed sleeves, and keep them mounted as long as the job is active. That way you minimize the need for new cylinders, and you save the time it takes to strip and file plates, remount them when a reorder comes in. Furthermore, you protect plates form being damaged, as often occurs during their removal from the mounting tapes.

Benefits:

Eliminates remounting plates for rerun

Gets repeat jobs on press faster

Saves cost of new plate cylinders

Prolongs life of plates and plate mounting tapes

Eliminates remounting plates for rerun

Gets repeat jobs on press faster

Saves cost of new plate cylinders

Prolongs life of plates and plate mounting tapes

GTSleeve HQ Speed

GTSleeve HQ Speed is a light-weight but robust sleeve for plate mounting with double-sided adhesive tapes available in thicknesses from 1 to 100 mm.HQ Speed has a polyurethane surface extremely resistant (75 Shore D). It is long-lived, light-weight, easily transportable and it assures a simple adhesive tape dismounting.

HQ Speed is available with glass fiber reinforcements and with edges covered by polyurethane. Besides, according to the sleeve thickness it is possible with brass notch or with stainless steel rings with incorporated notch.Other technical notes:

•Concentricity (TIR) = 0.025 mm

•Longitudinal tolerance as per DIN ISO 2768 T1 c

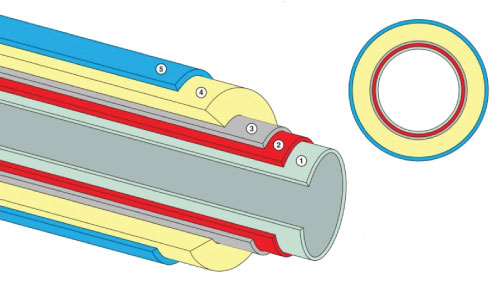

NON-CONDUCTIVE

① Fiberglass inner sleeve

② Compressible pre-compressed foam layer

③ Multiple layer in fiberglass

④ Light weight polyurethane 300 kg/m³ density

⑤ Polyurethane hardness 27 shore D

GTSleeve Speedy

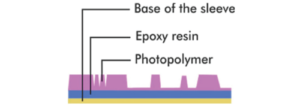

GTSleeve Speedy is a light-weight sleeve in fibreglass and epoxy resin suitable for several coating types and available in thicknesses from 0.8 mm to 1.4 mm.

Speedy suits all adhesive tape thicknesses and ensures excellent adhesion to all materials thanks to its fibreglass and epoxy resin surface, which is resistant to stress (fibreglass with epoxy resin reaches mechanical features 2.5 times more than polyester fibreglass, for the same weight) and to heat (resistant to vulcanisation temperatures up to 120° C). Speedy sleeves are durable with a

very long service life.

Other technical notes:

•Concentricity (TIR) = 0.025 mm

•Longitudinal tolerance as per DIN ISO 2768 T1 c

CONDUCTIVE GTSLEEVE HQ Speed

CONDUCTIVE GTSLEEVE HQ Speed is a conductive sleeve according to the ATEX 95 standard with controlled resistivity within a range of 0.01-0.09 MΩ within an applied DDP of 500 V, interaxis between the electrodes: 10 cm., Electrode bearing surface: 2 cm .x 10.5 cm. It is a light and sturdy sleeve for mounting plates with double-sided adhesive tapes available in thicknesses from 1 to 100 mm.

It has a new formulation that allows the use of nanometric aggregates giving properties which prevent the accumulation of electrostatic charges (ESD). This ability to dissipate static electricity has been obtained by maintaining excellent mechanical characteristics that gives it a great resistance (84-86 Shore D) and chemical properties of epoxy systems.

Available according to the thickness of the sleeve with brass notch or stainless steel ring with incorporated notch.

Other technical notes:

•Concentricity (TIR) ≤ 0.025 mm

•Longitudinal tolerance as per DIN ISO 2768 T1 c

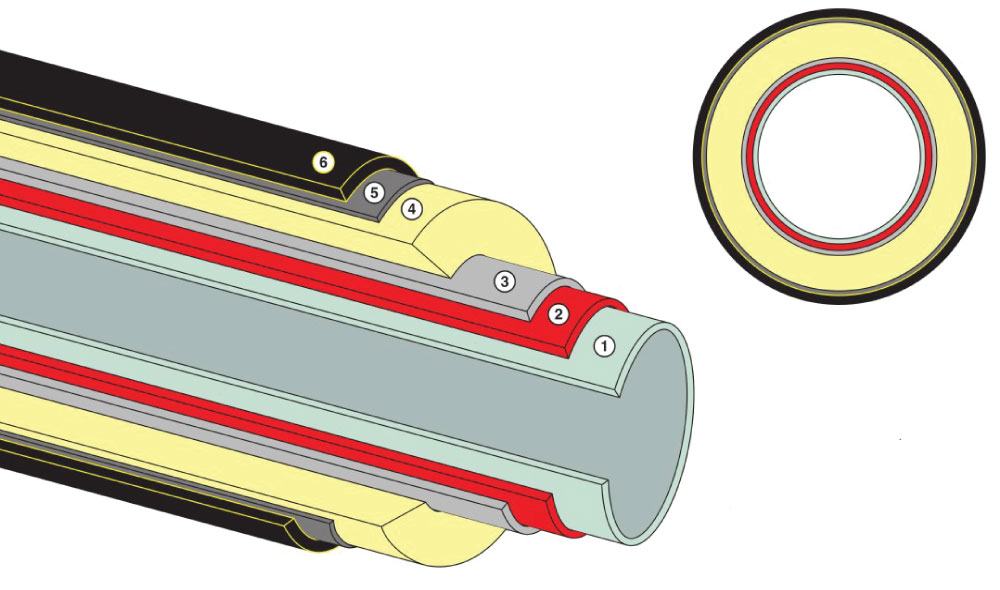

NON-CONDUCTIVE

① Fiberglass inner sleeve

② Compressible pre-compressed foam layer

③ Multiple layer in fiberglass

④ Light weight polyurethane 300 kg/m³ density

⑤ Polyurethane hardness 27 shore D

⑥ Conductive layer according to Atex 95 hardness 84-86 shore D

GT BRIDGE SLEEVE

GT BRIDGE SLEEVE can be realised in two different ways, aluminium or resin.

The material choice depends on the features of the printing unit on which it is mounted.

GT BRIDGE SLEEVE is realised on the basis of the mandrel and can also be done a

further air clutch in order to ease the sleeve clutch out of the machine.

GT BRIDGE SLEEVE can be combined with various types of sleeves; it reduces the

sleeve thickness saving provision costs for thick sleeves. Its extremely durable surface is generally scratch and solvent resistant if handled correctly (see our User's Advice).

It is available in antistatic version, too.

Further technical notes:

•Concentricity (TIR) = 0.025

•Tolerance on the length DIN ISO 2768t1 c

•Possibility to put positioning PIN

NON-CONDUCTIVE

① Fiberglass inner sleeve

② Compressible pre-compressed foam layer

③ Multiple layer in fiberglass

④ Light weight polyurethane 300 kg/m³ density

⑤ Polyurethane hardness 27 shore D

⑥ Conductive layer according to Atex 95 hardness 84-86 shore D

GT BIG SLEEVE

GT BIG SLEEVE is a light and robust sleeve for conventional plate mounting with adhesive tape.

GT BIG SLEEVE has an epoxy resin surface which ensures high resistance (70 Shore D) and consequently a superior lifetime. It ensures a simple adhesive tape dismounting. It is low weight and easy to handle.

Available in the following size:

Length: up to 3150mm

Diameter: up to 590mm

Thickness: from 1 to 100mm

In three versions:

BIG SPEEDY, BIG HQ SPEED AND BIG HQ ANTISTATIC

Further technical notes:

•Concentricity (TIR) = 0.025

•Tolerance on the length DIN ISO 2768t1 c

ELEFLEX

ELEFLEX is a sleeve that follows the Stork Standard Diameters. This sleeve is suitable for continuous printings with seamless photopolymer.

ELEFEX offers a high-resolution for both full-tone line printing and half-tone printing thanks to the thickness uniformity, which enables a perfect ink transfer. This guarantees also a very high register accuracy.

A completely seamless photopolymer sleeve suitable for continuous printing. Thanks to its uniform thickness, prefect ink transfer is achieved. Suitable for high-resolution line printing and/or half-tone printing. Choose between Eleflex 10 (for damped adapters) or Eleflex 30 (for normal adapters). Thickness: 1-1.5mm

Other technical notes:

•Concentricity (TIR) ≤ 0.025 mm

•Longitudinal tolerance as per DIN ISO 2768 T1 c

A completely seamless photopolymer sleeve suitable for continuous printing. Thanks to its uniform thickness, prefect ink transfer is achieved. Suitable for high-resolution line printing and/or half-tone printing. Choose between Eleflex 10 (for damped adapters) or Eleflex 30 (for normal adapters). Thickness: 1-1.5mm

GTSleeve Combi

GTSleeve Combi follows the Stork Standard Diameters. It is based on HQ Speed and can be coated with photopolymer.

Combi guarantees a top printing output even with the finest nets.

No adapter is needed with this high speed quality sleeve. It comes in Stork standard epoxy resin diameters and has a photopolymer coating. Thickness:>1,5mm

Adapters are not needed.

Other technical notes:

•Concentricity (TIR) = 0.025 mm

• Longitudinal tolerance as per DIN ISO 2768 T1 c

No adapter is needed with this high speed quality sleeve. It comes in Stork standard epoxy resin diameters and has a photopolymer coating. Thickness:>1,5mm

Adapters are not needed.

GT RUBBER

GT RUBBER is the RUBBER and POLYURETHANE coating line for your cylinders and your sleeves.

RUBBER guarantees resistance to chemical products, temperatures and its hardness is from 25 to 100 shore A.

POLYURETHANE offers better characteristics with resistance to abrasion, cutting, pressures and ozone.

Its hardness is from 30 to 95 shore A up to 75 shore D.

GT ROLLER

GT ROLLER is the new rolls line of GRAFICHE TAMBURINI for flexographic printing.

Manufacture aluminium, steel or chromium steel cylinders in order to meet every printing need.

On demand, cylinders can be done with certified and radiographed outlines.

All cylinders are balanced.

Care of sleeves & adaptors

In order to utilize sleeves and adapters in the most efficient way and to increase their lifetime, you should follow the following easy recommendations during all working phases.

Air pressure

• The air pressure measured at the air cylinder should be between 6 and 8 bar (87-116 psi).

• The air volume should not be below 12 litres per second (0.42 cubic ft/sec.).

• Please ensure air can pass freely without obstructions.

• Unnecessarily long or branching supply lines may lead to a drastic fall in air pressure.

• The compressed air system and the air cylinder surfaces should not be wet or dirty of oils, lubricants, and inks.

• Check for blockages in the air outlet from time to time.

Cleaning, care and storage of sleeves and adapters

• Lubricants, ink, and tape residues should be removed as quickly as possible to maintain unaltered surface properties for as long as possible.

• The only suitable solvents for cleaning are ethanol, propanol, and isopropanol.

• Stronger residues can be removed with a soft nylon brush.

• Do not use solvents containing grease or oil since they negatively affect the surface.

• Do not keep solvents on sleeves/adapters for a long period of time.

• Plates and tape should always be demounted after use so that solvents do not damage the sleeves.

• After cleaning, leave the sleeves/adapters to dry for about 30 minutes to allow the complete evaporation of solvents.

• Never use: acids, alkaline solutions, salt solutions, and sharp objects that could damage the sleeves/adapters

• To keep unalterated good mounting properties, the inner base of the sleeves should be cleaned with an appropriate cleaner.

• Fibre-glass filaments which could loosen from the inner base of the sleeve can be grinded off, but never pulled out.

• Sleeves/adapters should be stored freely and should not be stacked on top of each other or in contact with weights which may affect their concentricity.

• Please ensure that sleeves/adapters stored upright do not topple over.

• High temperatures and humidity negatively affect the service life of sleeves/adapters.

Flexo plates mounting

• Lubricant, oil and ink reduce the adhesion properties of the tape.

• To apply the tape on the sleeve without bubbles the use of a plastic rake and of a plastic roller is recommended.

• PVC/PE adhesive tapes effectively protect the exposed surface of the sleeve.

• If an edge sealer is used, never apply it directly on the sleeve, but only on the tape!

• Cutting directly on the sleeve might damage the surface.

• In order to avoid the edge lifting of the plate, adjust the tape gap and the plate gap by a minimum of 30°.

Flexo plates demounting

• Remove cliché carefully, slowly and with constant tension in order to avoid cliché damaging.

• Remove the tape by slowly pulling it back from the corner at an angle.

• Remove any tape residue immediately.

Contact us!

Enquiry Form

Head Quarters

8-1-364/B/72,Deluxe Colony, Toli chowki Sheikpet road

P.O.Golconda Fort -Hyderabad – 500008, Telangana State, INDIA

Or

Call Or E-Mail us on:

Call us on:

+91 720 785 0642

Call us on:

+966 50 133 4297

Email us at:

info@flexconsultantit.com

Email us at:

Sales@flexoconsultantit.com

Flexoconsultant IT

8-1-364/B/72,Deluxe Colony, Tolichowki Sheikpet road P.O.Golconda Fort, Hyderabad, 500008, Telangana, India