Introduction:

We are marketing agent & strategic partner for Vallis Technologies,Serbia who manufacturer of top performance machines using sophisticated technological solutions and best-quality equipment and components that can be found on the market.

– S10-Stack type gearless Flexographic Printing machine

– L10-Inmould (IML) Labels cutting machine

– R10-Slitting & Rewinding machine – SharpDrive -Die-cutting machine for Aluminium Rolls The art of engineering is rooted in the abundance of precision, speed and efficiency. It is perfectly aligned with its industrial purpose and represents indisputable triumph over all technical challenges encountered along the way. Our intention the users to recognize that these aspects have served as an inspiration for the Vallis brand.

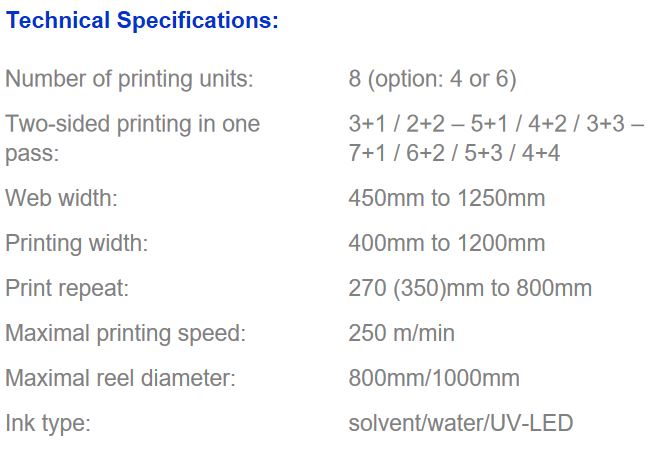

S10- Stack type gearless Flexographic Printing machine

About S10 - Stack type gearless Flexographic Printing machine

S10 is a stack type gearless flexographic printing machine with automatic register control. It is a flawless combination of advanced technological, mechatronical, electronic and software solutions. Complete electronic control, motors, drives and register control are realised with high-end integrated SIEMENS platform.

Numerous engineering innovations have been implemented for the first time on this model in cooperation with Siemens Application Center for printing technology from Erlangen, Germany. All printing, anilox and impression cylinders are driven by separate servo motors.

On-site visits can be arranged with S10 at full exploatation available for full inspection, where you can hear first-hand user experience from the operators working on this machine.

Features:

- Inking system: closed chamber doctor blade (with pneumatic pressure regulation)

- Ink air mixers

- Anilox and Plate sleeve system for fast change

- Complete electronic control and motion system from one supplier: SIEMENS

- Servo driven each printing (plate) cylinder

- Servo driven each anilox cylinder

- Print repeat modification for up to 2%

- Servo driven side register

- Four servo drives control positions of anilox and plate cylinders (for each printing unit)

- Automatic impression settings

- Servo driven unwinder and rewinder

- Digital web tension control

- Full automatic register control (length and side) (BST-eltromat camera)

- Automatic web edge guides (BST)

- Drying system: two separate controlled systems (digitally adjustable drying: horizontal tunel after printing and between printing units)

- Web-view system (BST)

- Industrial touch screen PC system for centralized control and monitoring

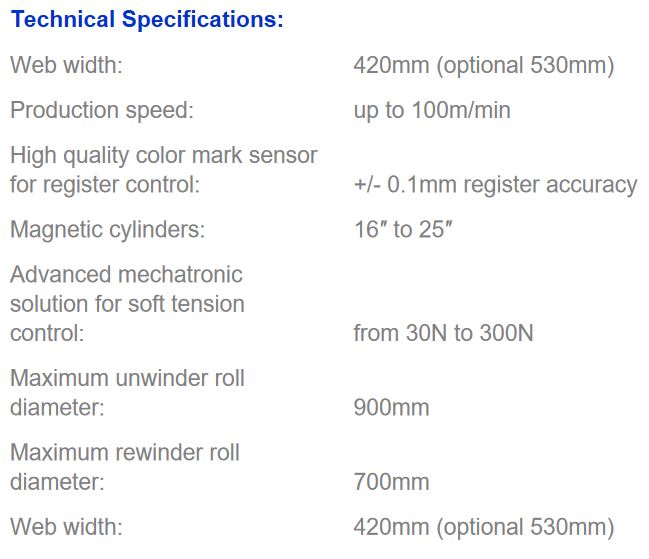

L10- Inmould (IML) Labels cutting machine

About L10- Inmould (IML) Labels cutting machine

L10 is a sophisticated high-end machine for high speed production of IML labels from printed rolls. Beside basic version with simple stack at the end of conveyor, Vallis offers a model with delta robots for labels stacking (one or two robots, depending on desired production speed).

Robotic stacking provides higher degree of automatization and continuous production (each robot has one stack for stacking and another for replacement). Also it is possible to combine different shapes and sizes on the same print format thus optimizing material usage. One robot provides production rate up to 35m/min.

Features:

- Edge/line guide system (specific line guide sensor)

- Kocher-Beck cylinders for rotary die-cutting

- Labels assembly into a stack at the end of conveyor (basic version) or with delta robots

- Robotic assembly provides continuous production

- Two assembly stacks for each robot

- Automatic roll end detection

- Fast and easy roll change

- Automatic detection of material juncture on backside

- Complete electronic control and motion system from one supplier: SIEMENS

- User friendly interface via 15” screen industrial PC

- Easy and felxible system adjustments, interface language according to customer demand

- Optional mobile operator panel

- Full diagnostics via touchscreen

- Remote internet connection and service

R10- Slitting & Rewinding machine

About R10- Slitting & Rewinding machine

Unwinding unit

Unwinding unit is completely separate from main machine unit. There is a safe pass between these two units for operator’s easy job setting and monitoring during run.

Shafless core chucks for 3’’ and 6’’ (76mm and 152mm) core I.D. Siemens Sinamics S120 servo drive system.

Roll diameter up to 1100mm.

Servo driven unwinder perfectly maintains compensation roller in reference position (measured by precise linear magnetic encoder).

Digital tension setpoint via I/P proportional pressure valve. Tension range: 30-300N

Web break detection. Splice table after unwinder.

Hydraulic roll loading (lifting).

Web line/edge guide

BST CLS Pro 600 web edge/line guide system after unwinder

(±50mm).

Infeed section

Servo driven infeed rollers (S-wrap). Siemens Sinamics S120 servo

drive system. Bowed (banana) roller (driven).

All idle rollers are cork-rubber covered and dynamically balanced.

Slitting section

Razor slit in air/groove.

20 razor blade magnetic holders.

Automatic vertical razor blade oscilating (moving up/down during

run). Manual knife positioning.

Laser guided knife positioning system with digital position display.

Adjustable material heigth to female knife shaft.

Basic trim extraction system. Trim width range: 5-20mm

Rewinding unit

Two differential friction shafts on rewinders for core I.D. 3’’. Friction ring width 20mm. Siemens Sinamics S120 servo drive system.

Roll diameter up to 620mm.

Max. roll weight on one shaft: 400kg

Digital tension control via I/P proportional pressure valve.

Max. tension for both shafts in total: 500N (at min. diameter), 300N (at max. diameter) Taper curve adjustable in 16 points.

Lay-on rollers for both shafts (automatically seaprately digitaly adjustable pressures). Minimal slitting width: 40mm

Laser guided core positioning system with digital position display. Unloading stand with two mandrels, manually pivoting, length 1050mm. Two rewind antistatic devices.

Features:

- Shaftless unwind

- Splice table (option)

- Hydraulic lifting of parent roll

- AC digital servo technology (unwind, main drive, rewind)

- BST Web guide system (edge or line giuded)

- Edge trim suction unit

- Differential friction shafts on rewinders

- Laser guided core positioning system

- Antistatic devices

- Unloading device for rewound rolls

- Full digital tension control

- 12`` color touch panel

- Remote service access via safety internet router

- Unlimited job settings storage (recipes)

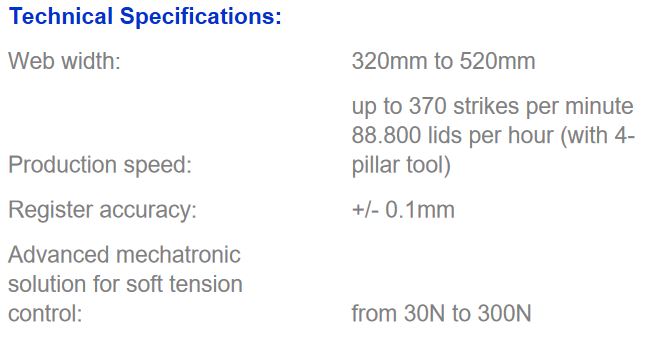

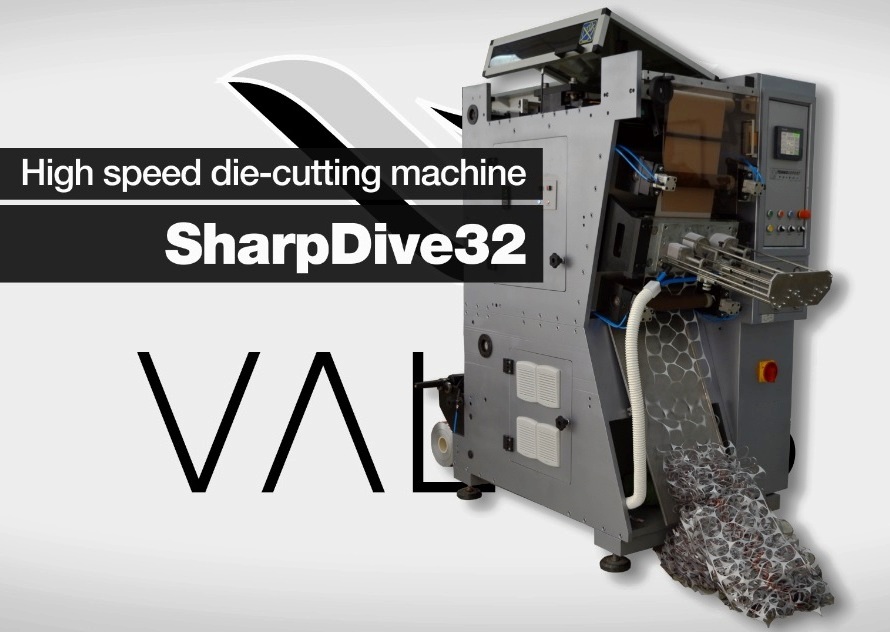

SharpDrive-Die-cutting machine for Aluminium Rolls

About SharpDrive-Die-cutting machine for Aluminium Rolls

SharpDive is a sophisticated high-end machine for high-speed die-cutting production from printed aluminium rolls. Its most prominent features are efficiency and functional reliability, meaning that user can count on uninterrupted production over three eight-hour shifts, seven days a week.

SharpDive daily production capacity is over 1.5 million units produced if 4-pillar tool is used, or about 2.7 million units with 7-pillar tool. The machine has built-in soft tension control which guarantee perfect engraving at full production speed.

On-site visits can be arranged with SharpDive at full exploatation available for full inspection, where you can hear first-hand user experience from the operators working on this machine.

Features:

- High quality color mark sensor for register contro

- Automatic format length adaptation, no need for manual correction

- High quality 4-pillar (or more) die-cutting tools

- Automatic roll end detection

- Fast and easy roll change A

- Automatic detection of material juncture on backside

- User friendly interface via 5,7” touch-screen (optional 10” and 15” touch screens available)

- Easy and felxible system adjustments, interface language according to

customer demand

- Optional mobile operator panel

- Full diagnostics via touchscreen

- Remote internet connection and service

Contact us!

Enquiry Form

Head Quarters

8-1-364/B/72,Deluxe Colony, Toli chowki Sheikpet road

P.O.Golconda Fort -Hyderabad – 500008, Telangana State, INDIA

Call Or E-Mail us on:

Call us on:

+91 720 785 0642

Call us on:

+966 50 133 4297

Email us at:

info@flexconsultantit.com

Email us at:

Sales@flexoconsultantit.com

Flexoconsultant IT

8-1-364/B/72,Deluxe Colony, Tolichowki Sheikpet road P.O.Golconda Fort, Hyderabad, 500008, Telangana, India